APPLICABLE INDUSTRY

Asan Plant 1

O.N has established an integrated production system capable of handling design review, machining, assembly,

and inspection for equipment modules and mechanical/electrical assemblies used in automation and semiconductor front- and back-end processes.

Tailored to the high-cleanliness and high-precision requirements of the automation and semiconductor industries,

we provide assembly in cleanroom environments and a customized quality assurance system to meet the stringent quality demands of our customers.

and inspection for equipment modules and mechanical/electrical assemblies used in automation and semiconductor front- and back-end processes.

Tailored to the high-cleanliness and high-precision requirements of the automation and semiconductor industries,

we provide assembly in cleanroom environments and a customized quality assurance system to meet the stringent quality demands of our customers.

Main Business Areas

01

Assembly Capable in Cleanroom Environment.

- We operate a cleanroom of approximately 1,200 pyeong (~4,000 m²), compliant with Class 10,000 standards. It is designed to prevent external contamination, control static electricity, and maintain stable temperature and humidity, ensuring optimal conditions for precise assembly.

02

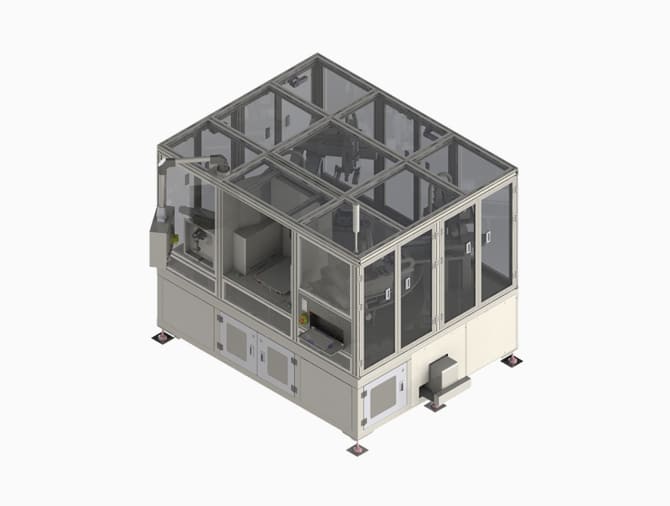

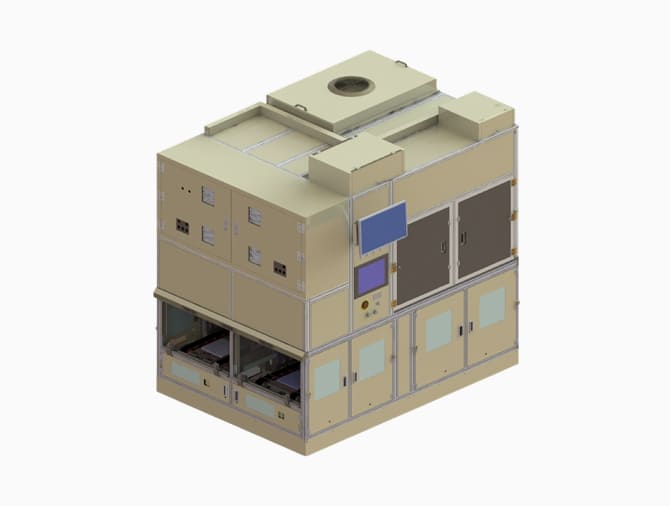

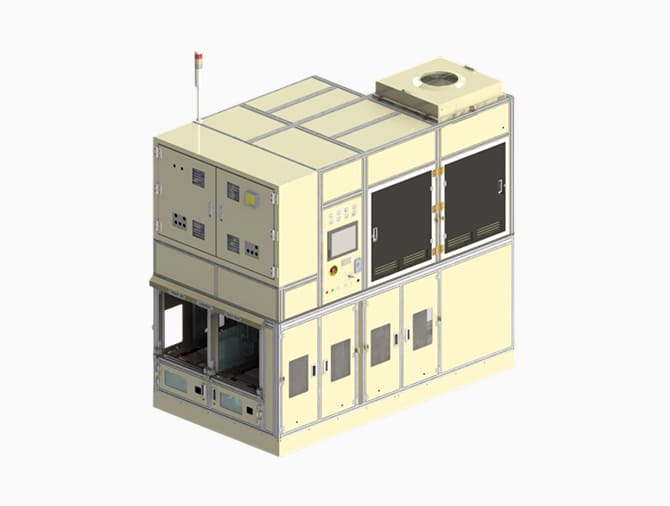

Precision Equipment Assembly

- Assembly process planning based on design drawings

- Design and assembly of equipment modules for front-end and back-end semiconductor processes

- High-precision processes to meet strict dimensional tolerances and shape conformity

- Utilization of jigs for leveling, squareness, and flatness standards

03

Module Assembly, Reliability Verification & Final Inspection

- BOM-based component configuration and assembly schedule management

- Reliability verification and final shipment inspection

- Full-component management, including both in-house machined and outsourced parts

04

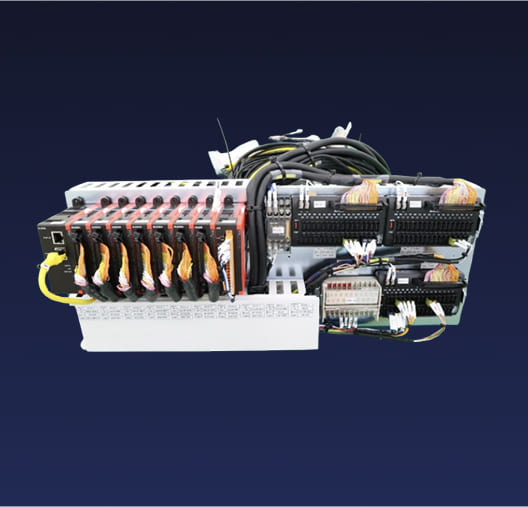

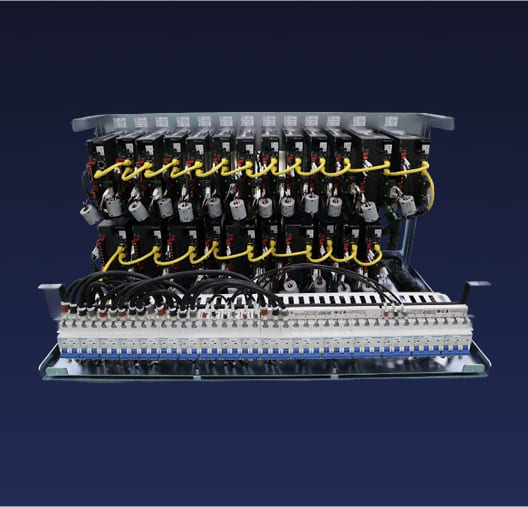

Possess capability in manufacturing electrical boxes and controllers

- Possess capabilities in assembly, wiring, housing, terminals, and functional testing of electrical and electronic components

- Assembly and wiring of various electrical components such as PLCs, relays, circuit breakers, terminal blocks, and wire crimping

- Strong ability to provide customization according to customer specifications

05

Integrated mechanical part machining and assembly

- In-house machining and assembly using company-owned equipment

- BOM-based material management and procurement, including outsourced parts

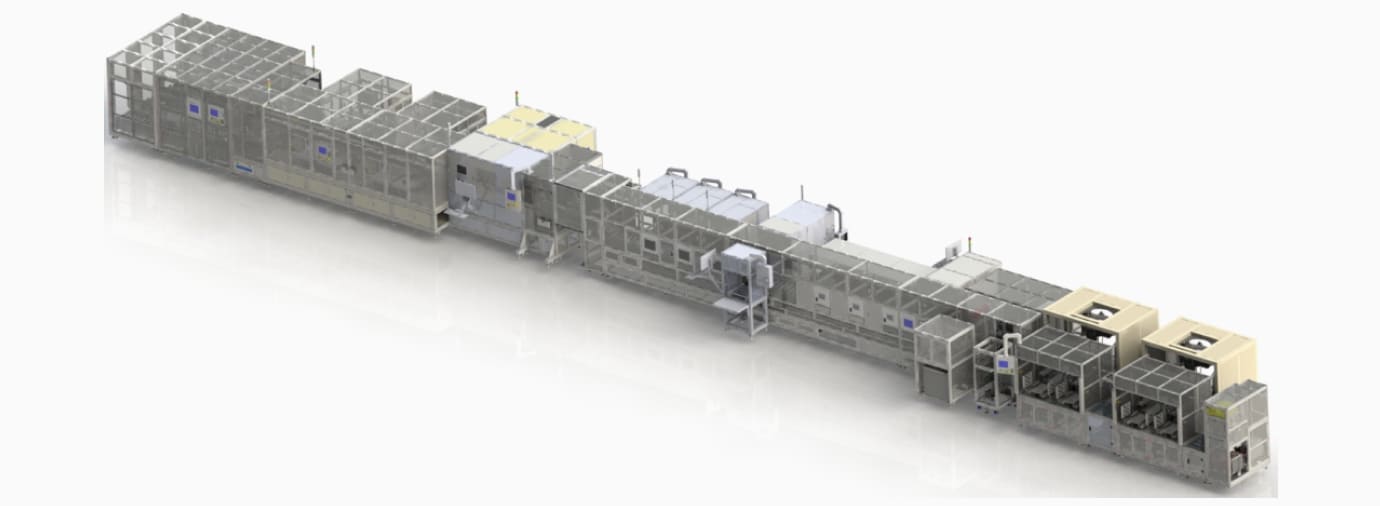

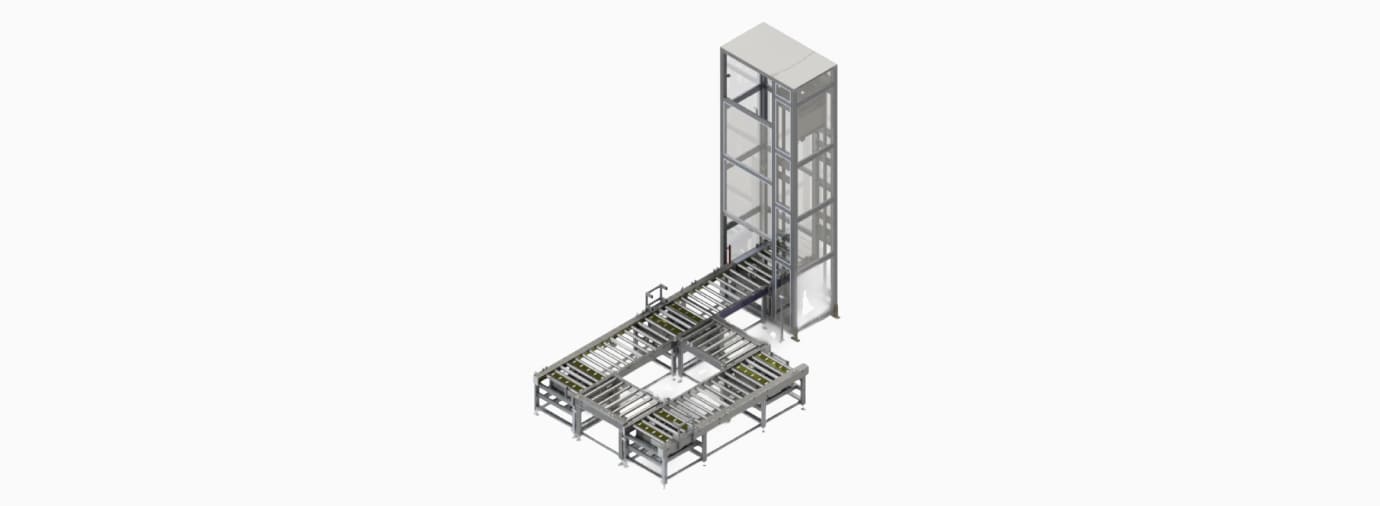

Manufactured Products

- ASSEMBLY

- Semiconductor Post-Process Test Package Equipment (OEM)

- *Refer to images on the customer’s website

- Semiconductor Full-Process Clean Equipment (OEM)

- *Refer to images on the customer’s website

- Automation Equipment (ODM)

- Custom Equipment Development and Manufacturing (ODM)

- Electrical Box

- Electrical Box Functional Testing

- Mechanical Performance Testing