APPLICABLE INDUSTRY

Vietnam Plant

O.N VINA serves as the global production hub of the O.N Group, located in the Ho Chi Minh region of Vietnam.

This facility specializes in precision machining and module assembly, producing components and

equipment modules for advanced industries such as semiconductors, displays, and medical devices.

It possesses expertise in precision sheet metal processing and welded structural assemblies,

along with the capability to perform assembly in high-cleanliness cleanroom environments.

This facility specializes in precision machining and module assembly, producing components and

equipment modules for advanced industries such as semiconductors, displays, and medical devices.

It possesses expertise in precision sheet metal processing and welded structural assemblies,

along with the capability to perform assembly in high-cleanliness cleanroom environments.

Main Business Areas

01

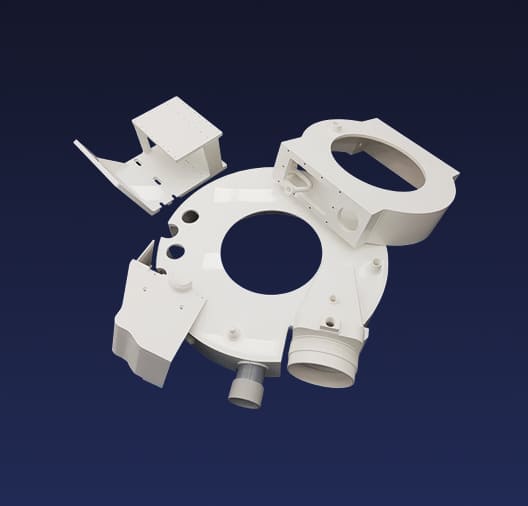

Precision Machining and Assembly

- Possess capabilities in CNC/MCT/multi-axis/router machining and precision polishing of metal and resin materials, and high-precision assembly of semiconductor, solar, and medical device components.

02

Cleanroom-Based Production

- Cleanroom assembly of electronic components and equipment modules

- Maintains cleanliness and consistent temperature/humidity to ensure assembly precision

03

Hot Air Plastic Welding

- Precision plastic welding technology for uniform joining of synthetic plastic materials

- Applicable to various industries, including semiconductors, automotive, and medical devices

04

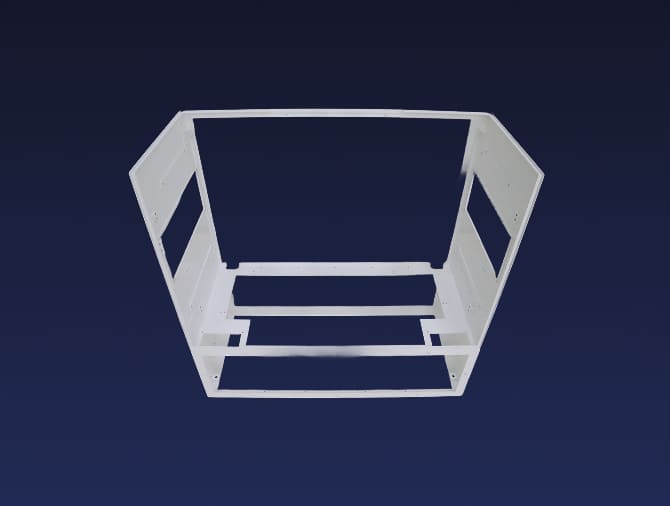

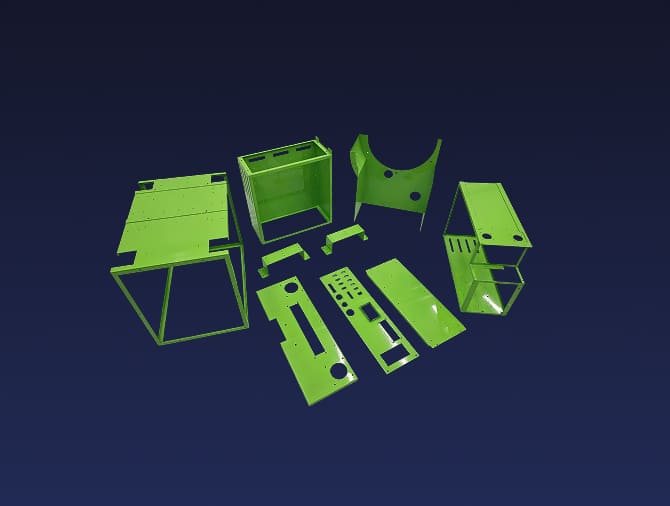

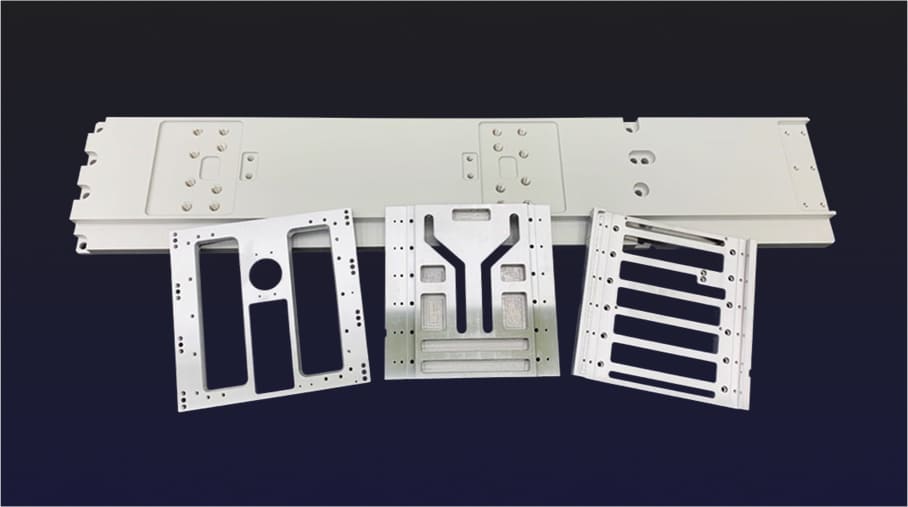

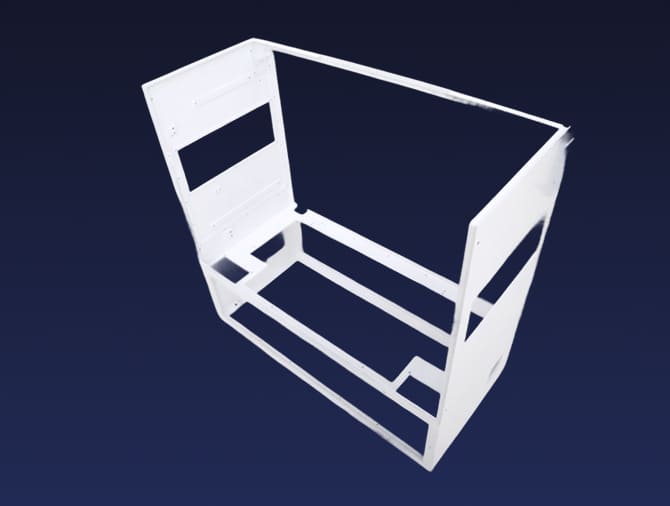

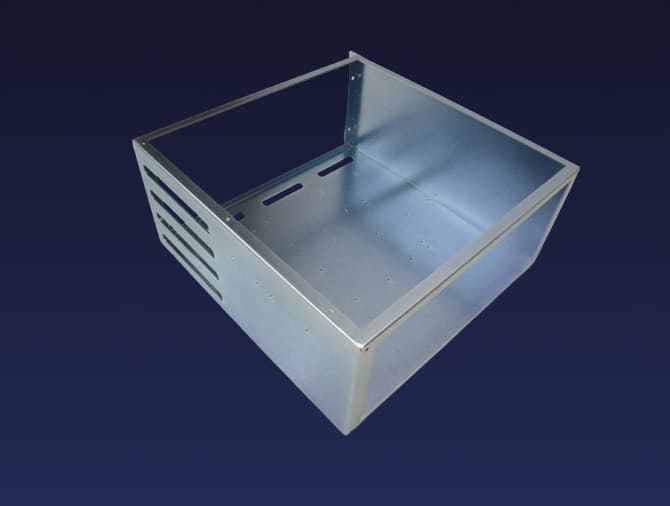

Sheet Metal Processing

- Laser cutting, NCT punching, bending, tapping, and pre-welding processing for various materials such as SUS, AL, and SPC

- Capable of precision machining with dimensional tolerances below ±0.1 mm

05

Fabrication and Welding

- Application-specific welding including CO2, arc, and TIG welding

- Post-welding treatment to ensure structural strength while minimizing slag and oxides

- Ensures both mechanical strength and aesthetic precision

06

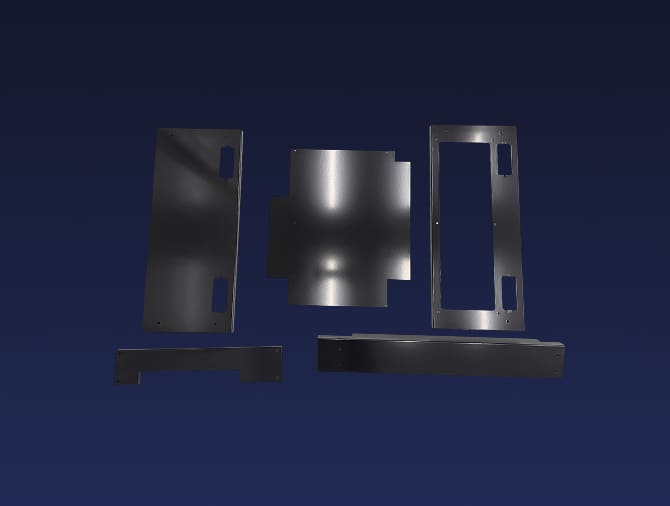

Post-Processing Coating and Finishing

- Supports various finishing processes such as sanding, deburring, powder coating, anodizing, and zinc plating

- Capable of applying specified colors and coating methods according to customer requirements

07

Import, Export, and Global Supply Chain

- Import of raw materials and components from countries such as Korea and Japan

- Export of finished products to Korea and other countries

Manufactured Products

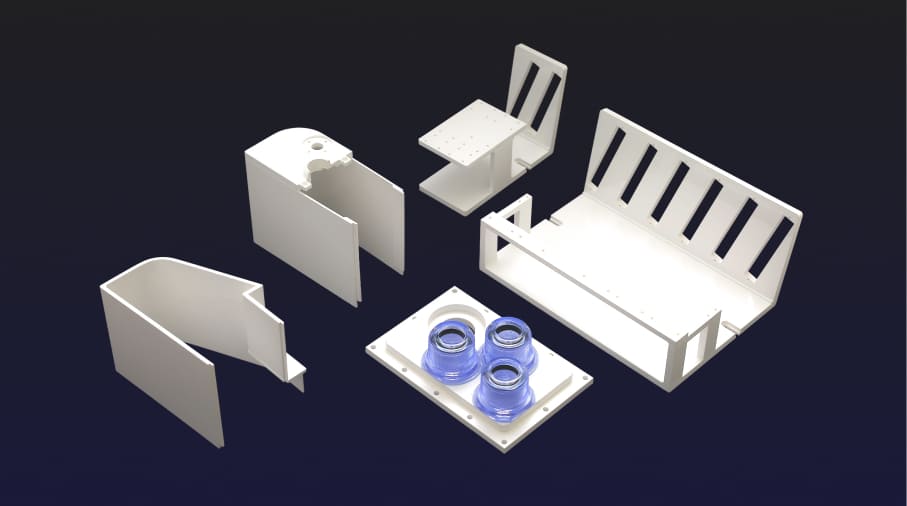

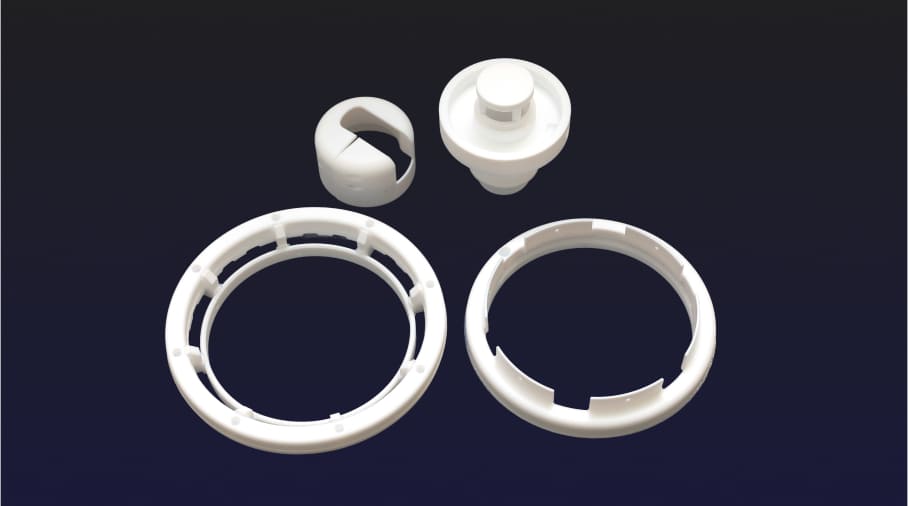

- Metal Machined Parts

- Plastic Machined Products

- Plastic Welding Parts

- Metal Machined Products

- Powder Coating